Maximize Material

Cost Savings

Deploy optimized mix designs into

production faster

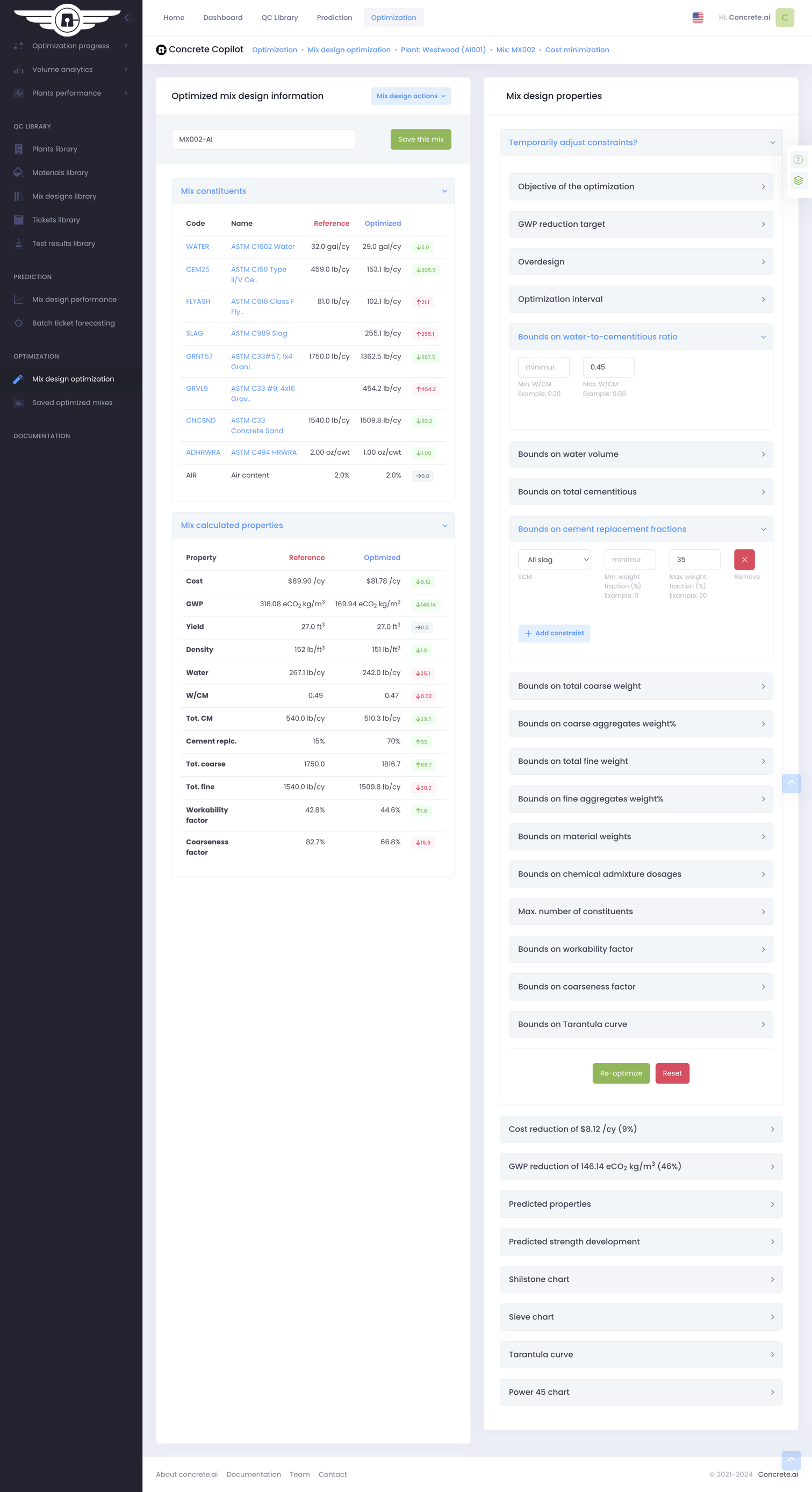

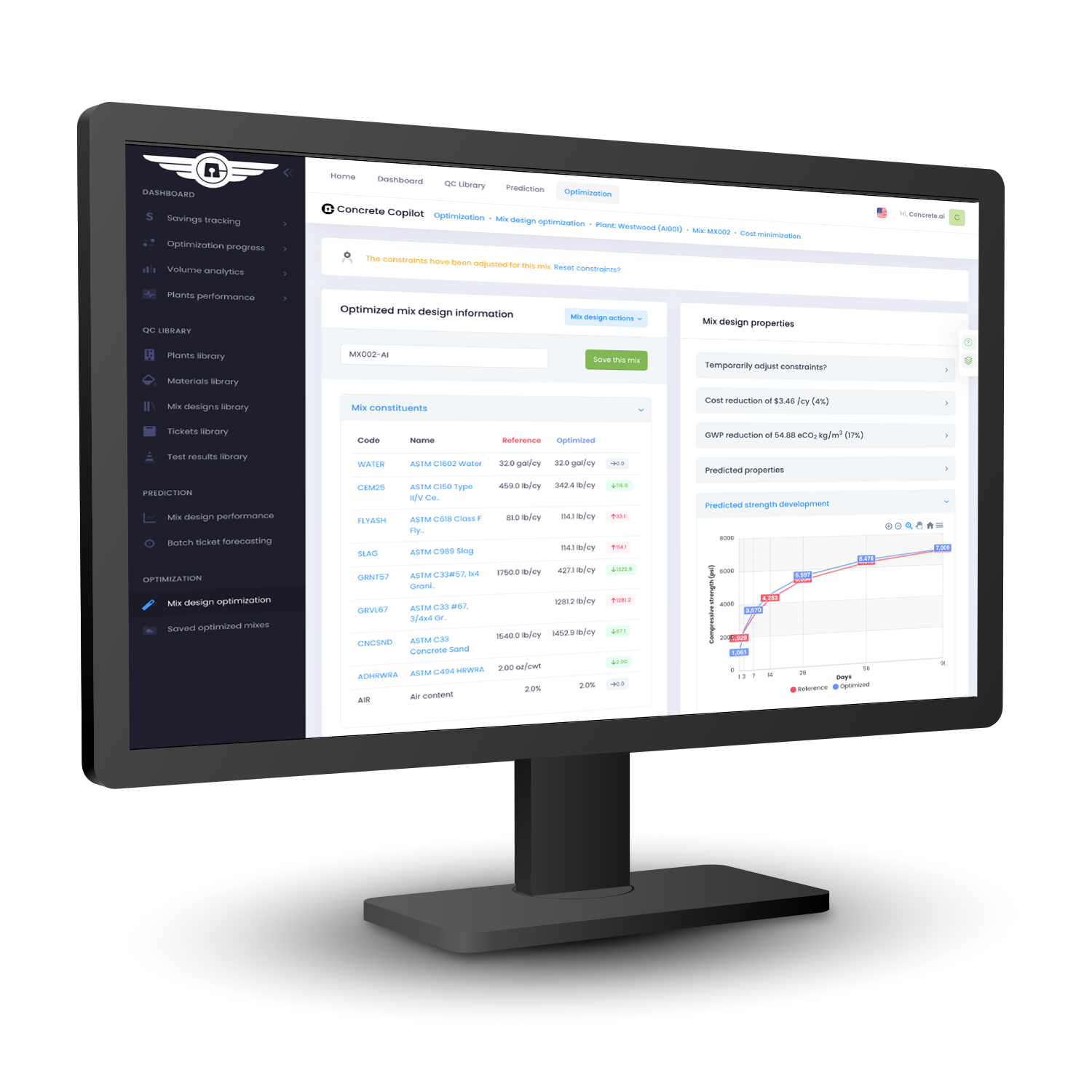

By using generative AI, Concrete Copilot creates millions of possible mix designs that empower producers to identify the optimal concrete recipe for any application. Each design meets rigorous engineering, safety, and performance requirements while also reducing the embodied carbon of concrete. Our platform accurately predicts the performance of these mixes in seconds, streamlining the design process from weeks to minutes. This efficiency saves producers money, improves productivity, and can help achieve a 30% reduction in embodied carbon in less than a month.

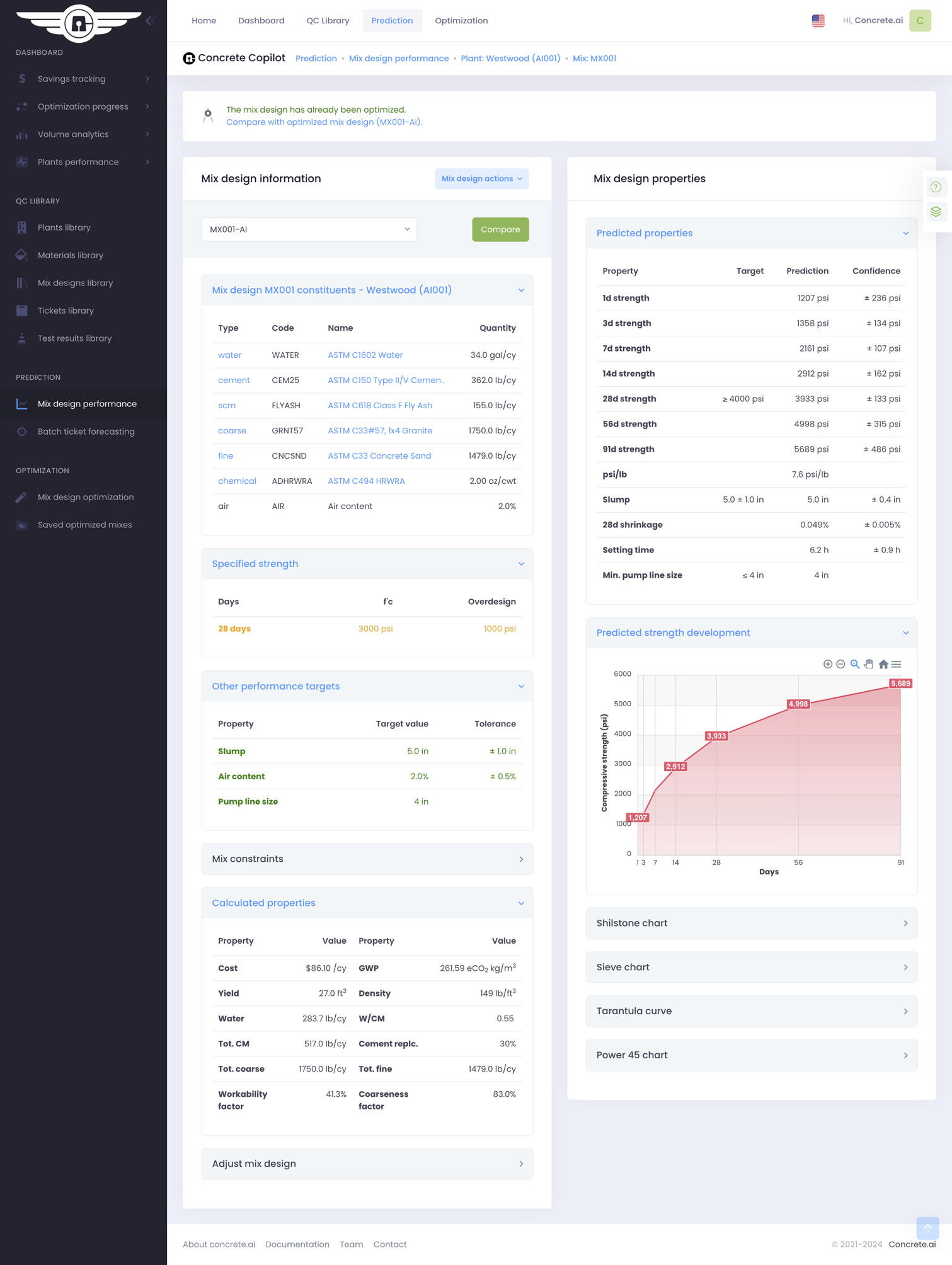

Rapidly

Predict Performance

Seamlessly integrated with a concrete producer’s current and historical data, Concrete Copilot selects optimal mix designs in seconds, streamlining the design process from months to minutes.

View web app screen

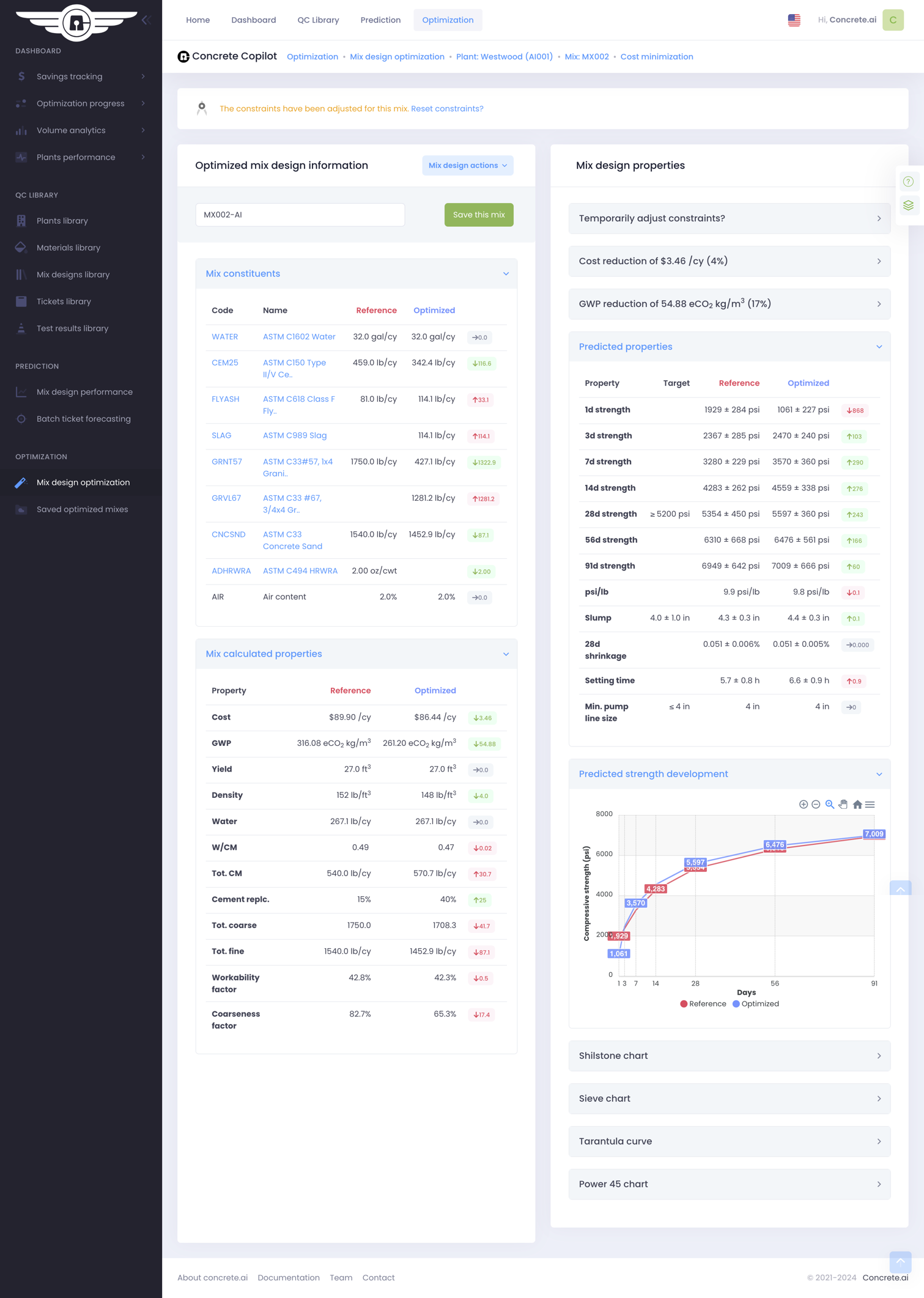

Not only do we pinpoint mix designs for the lowest costs, but Concrete Copilot quickly identifies fluctuations in raw material costs, making sure producers never miss cost savings opportunities.

View web app screen

Reduce

Material

Costs

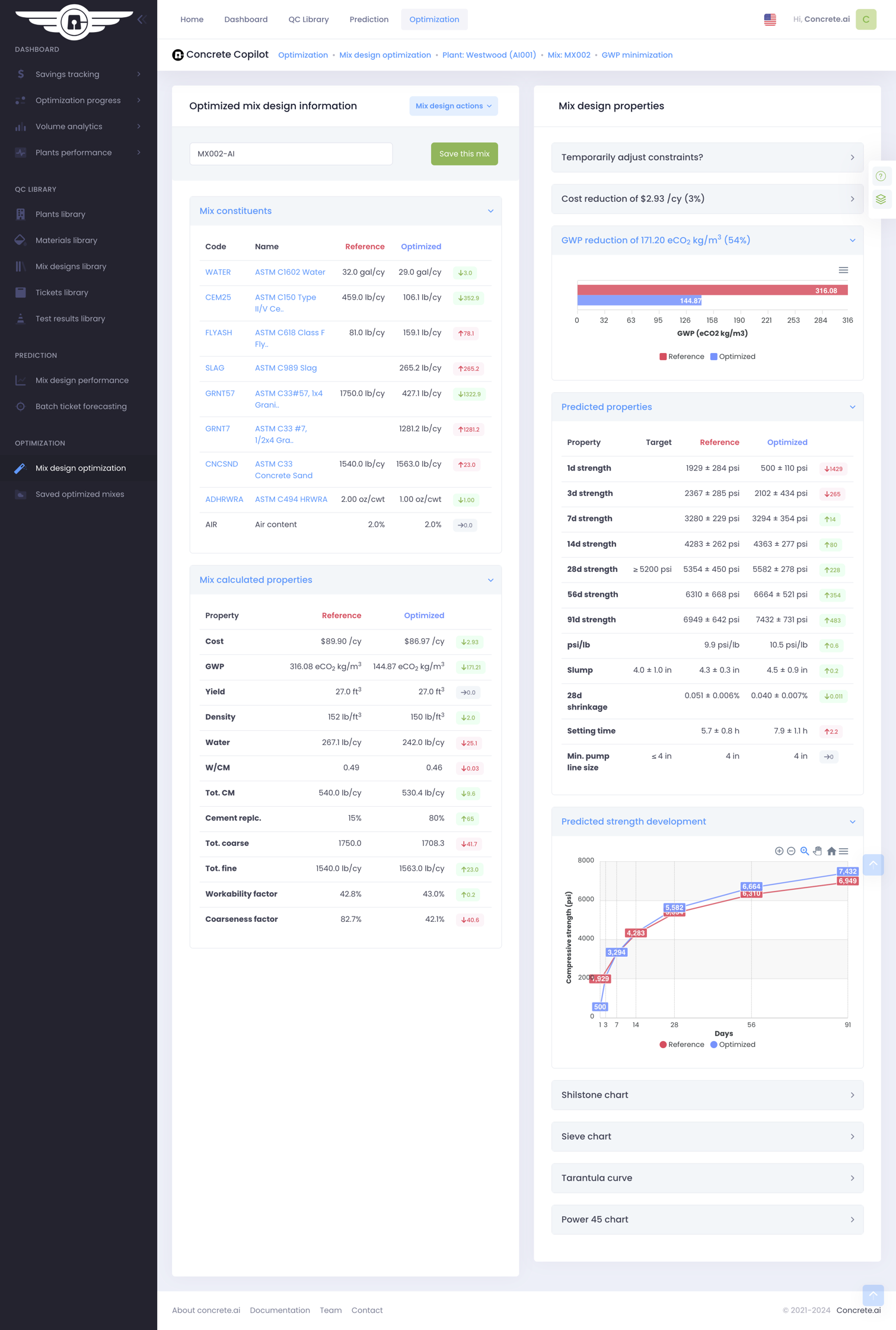

Lower

Your Carbon

Footprint

Carbon footprint is a design criterion integrated into the Concrete Copilot, allowing producers to quickly respond to requests for lower embodied carbon mixes.

View web app screen

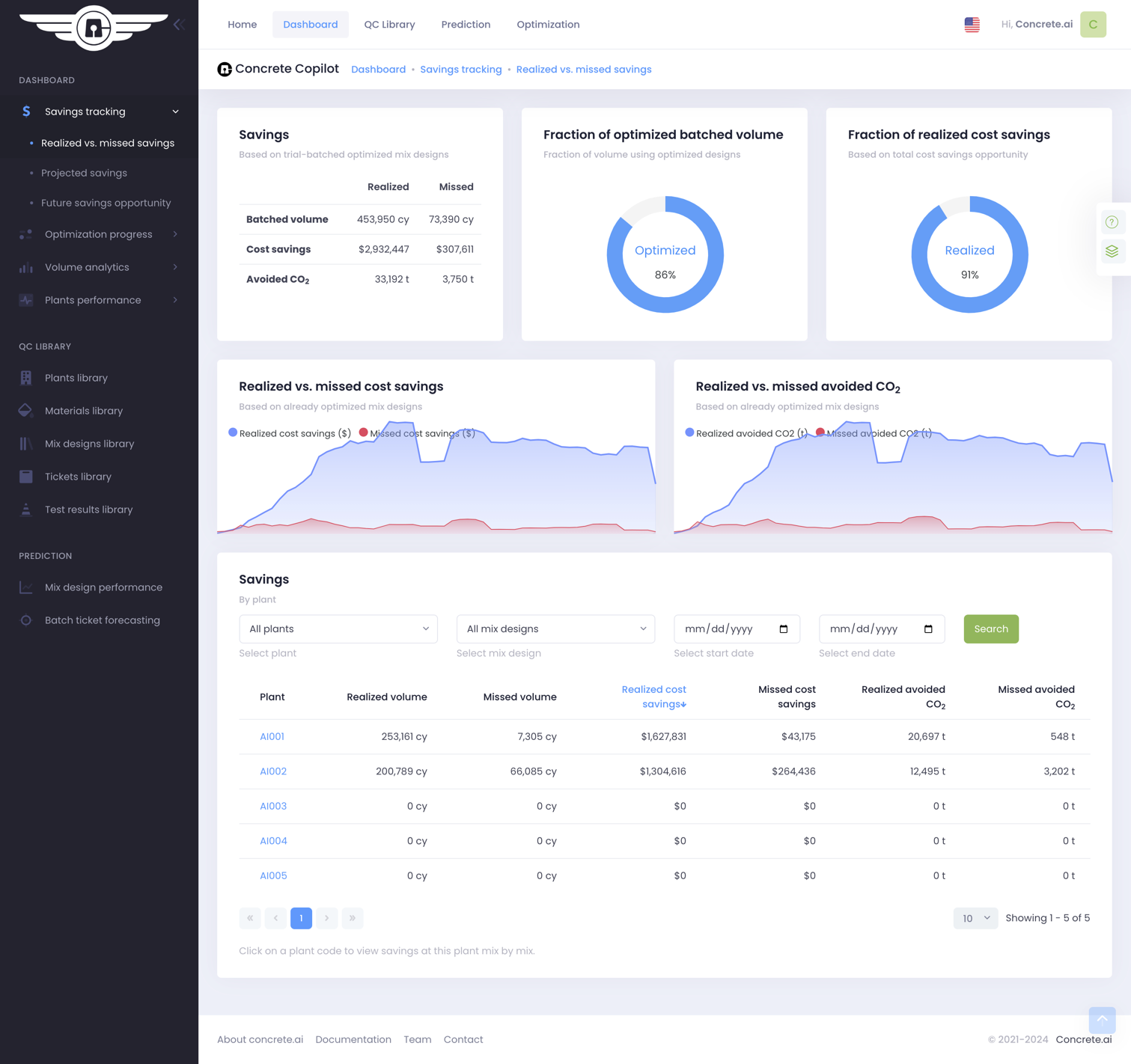

Our platform generates mixes that are optimized for any combination of cost, performance, and carbon reductions, empowering you to select the best mix for each use case. You never need to choose between cutting costs and reducing carbon.

View web app screen

Optimize

For Cost and

Carbon

Power

In Your

Hands

We believe the final decision-making needs to be in your hands. As a result, we have merged what big data and AI does best – to take enormously, complex data and process it in real-time – with the best of what experienced engineers and concrete professionals offer – human judgement – creating a new pathway to optimized mix designs.

View web app screen

THE CONCRETE COPILOT

DIFFERENCE

With just 1-2 hours of training, producers can optimize their mix designs with an intuitive user interface that seamlessly connects to the QC software producers use to extract all relevant data.

Concrete Copilot does not add any extra step into the existing quality testing routine of the producers, unlike some solutions that require testing the mixes in their own labs, slowing down the ability to scale while duplicating efforts.

The platform helps producers effectively adapt to users’ data and model different scenarios. It can use the materials in their supply chain or adjust new mix designs on demand when (1) a new material becomes available, (2) an existing material is not available, or (3) the cost, carbon footprint, or performance of a material changes.

Producers see immediate cost savings and reduction in carbon when new materials become available.